The thermo-catalytic reforming process (TCR® process) developed through a collaboration between MUEGGE and the Fraunhofer Institute for Environmental, Safety and Energy Technology (Fraunhofer UMSICHT) produces synthetic natural gas, pyrolytic carbon, and synthetic crude oil. Process water is used in the TCR® process; after the process, the water is contaminated with organic compounds like acetonitrile, acetic acid, phenol, pyridine, and pyrroles. For the process water to be recycled, these organic compounds must be removed. MUEGGE’s atmospheric pressure microwave plasma torch [1] was applied for the decontamination of process water.

1. Atmospheric pressure microwave plasma setup for the decontamination of process water

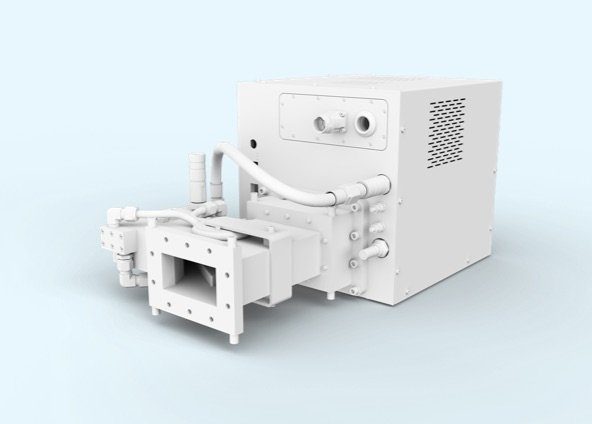

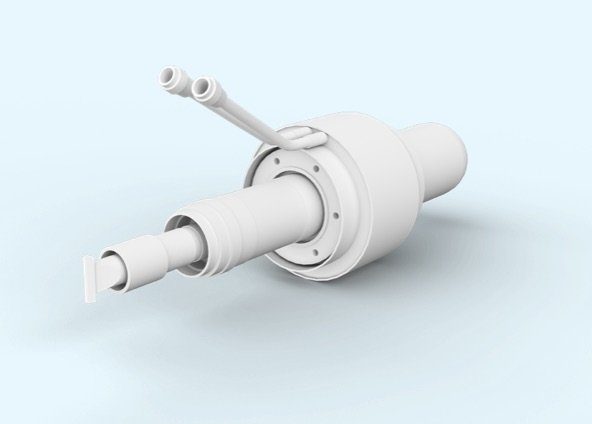

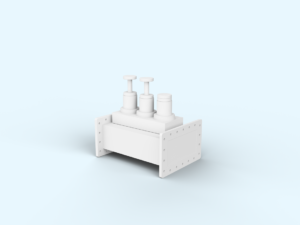

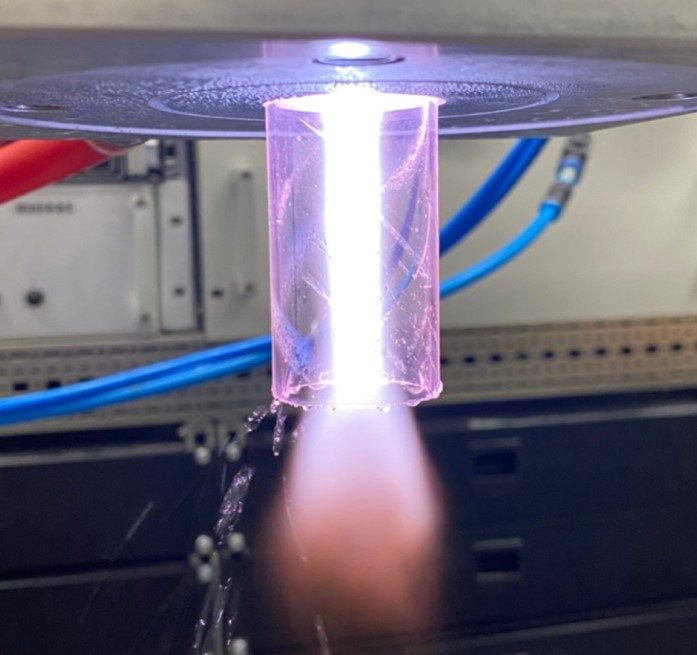

The decontamination of the process water was performed by Fraunhofer UMSICHT using MUEGGE’s atmospheric pressure microwave plasma torch operated with air at 2.45 GHz, see Figure 1. The treatment process consists of swirling compressed air into the contaminated process water and to inject the resulted air-water flow via a venturi nozzle into the MUEGGE 2.45 GHz plasma torch as to form tiny droplets of water [2]. The smaller the droplets of process water in the pressurized airstream, the higher the probability for complete dissociation of the organic compounds in the high-energy microwave plasma. The desirable result of this atmospheric pressure plasma cleaning process would be the complete conversion of the organic compounds into water vapor and carbon dioxide after dissociation and reaction with hydroxide- and oxygen-radicals formed within the microwave plasma.

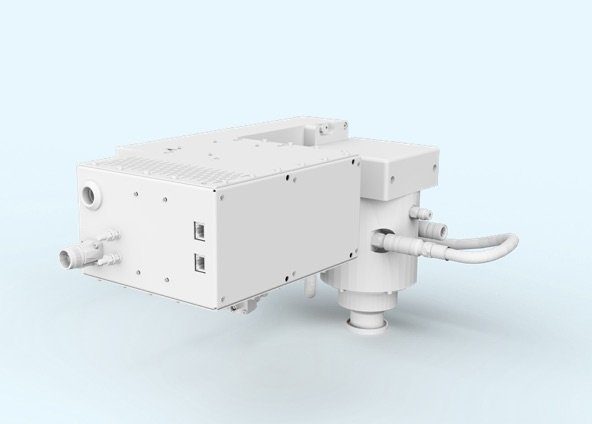

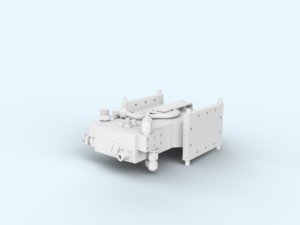

At the exit of the 2.45 GHz air plasma, the decontaminated process water can be easily recaptured by rapid cooling, as shown in Figure 2.

To demonstrate the efficiency of the atmospheric pressure microwave plasma decontamination of process water, solutions of 8.74 g ethanol and 16.81 g acetic acid dissolved in 1 l of distilled water were used as substitutes of the organic compounds in the laboratory scale experiments performed by Fraunhofer UMSICHT.

2. Results of the plasma decontamination tests using a solution of ethanol

A solution of 8.74 g of ethanol in 1 l of distilled water was injected in compressed air and fed into the atmospheric pressure microwave plasma with a flowrate of 130 l/min, which corresponds to a flowrate of approximately 65 ml/min of the test solution. According to the results obtained by Fraunhofer UMSICHT, the proportion of ethanol dissolved in distilled water was reduced by 92% after its treatment in the air microwave plasma using 2 kW of microwave power.

3. Results of the plasma decontamination tests using a solution of acetic acid

A test solution of 16.81 g of acetic acid in 1 l of distilled water was added into compressed air and fed into the atmospheric pressure microwave plasma with a flowrate of 130 l/min, which corresponds to a flowrate of approximately 65 ml/min of the test solution. Measurements of the content of acetic acid dissolved in distilled water showed a reduction by 88% after its treatment in the air microwave plasma operated at 2 kW of microwave power.

4. Conclusion: Successful and efficient decontamination of the process water by atmospheric pressure microwave plasma

The laboratory experimental results have shown 92% reduction of ethanol and 88% reduction of acetic acid using the atmospheric pressure air plasma at 2 kW microwave power.

These preliminary results are very promising for high efficiency cleaning of process water from TCR® applications. Working at elevated microwave power levels (e.g., MUEGGE’s 75 kW APS @ 915 MHz) will allow the removal of significantly higher quantities of organic contaminants and the process of considerably higher flows of contaminated process water.

References

[1] Müller, Robert and Gorath, Moritz, et al.: Atmospheric Pressure Plasma Source and Downstream Source: Characteristics and Industrial Applications, Invited Talk, Contributions to 56th Annual Microwave Power Symposium (IMPI 56), Savannah, Georgia (USA), June 14-16, 2022.

[2] Kaiser, Nadine: Behandlung von schwach kontaminierten Abwässern mittels Plasma-Technologie (Treatment of low-contaminated residual water using plasma technology), Bachelor’s Thesis, Technische Hochschule Nuremberg „Georg Simon Ohm“, August 4, 2021.