Fast, efficient, flexible. For many years already the process design in high performance vulcanization is revolutionized by microwave and microwave-hybrid-applications. The advantages are very obvious; you swiftly reach a high vulcanization temperature and hence significantly reduce your exposure time. The precise design of the microwave-antennas, optimized in 3D simulation calculations, can also make your vulcanization processes significantly more efficient. Refresh and deepen your knowledge about this efficient vulcanization technology with an expert’s dive into the winning attributes of microwave applications.

Homogenous core temperatures over any strand cross-section

Microwave and microwave-hybrid-applications are perfectly suitable for the heating and vulcanization of synthetic and caoutchouc polymers since these polymer blends absorb electromagnetic waves very well. The typical polymers such as EPDM (Ethylene propylene diene monomer rubber), NBR (Nitrile butadiene rubber) or SBR (Styrene butadiene rubber) absorb over a wide temperature range between 10 °C and 170 °C nearly the complete amount of energy that is provided in the microwave frequency bands around 2.45 GHz and 915 MHz. It is also possible to create application and process variations by a microwave additional heating to reach higher vulcanization temperatures faster and therefore reduce the exposure time significantly.

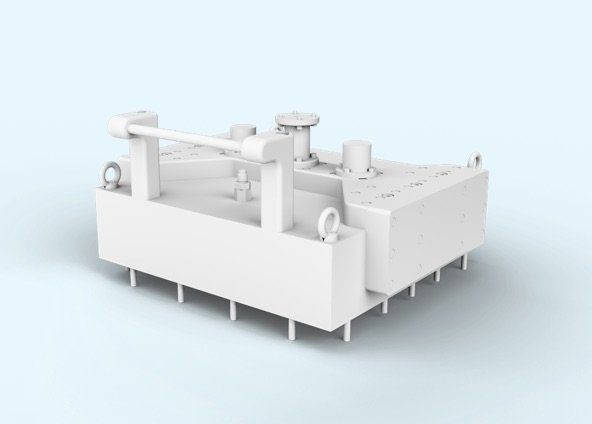

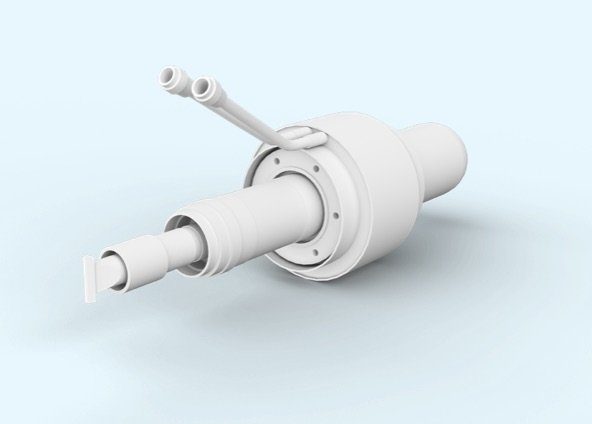

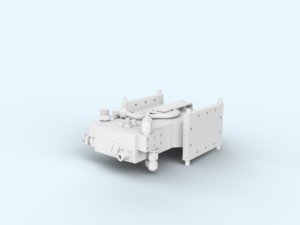

3D simulation based antenna and channel design

The design of the microwave-injecting antennas has a crucial influence on the aspired energy distribution in the heating channel. Corresponding to the aim a strong focus on profiles or profile areas is as possible as a homogenous filling of the entire cavity for the processing of highly porous foam and sponge rubber products. For positioning and alignment of the individual antennas of the microwave system are crucial the entire dimensions of the channel cross section as well as the character of walls and transportation system. Using 3D simulation calculation during the design of the heating area we optimize the ideal radiation geometry, alongside the transport direction or across the material cross section as well as the type of the microwave antenna. At the same time it is possible to take in to account of high-density profile areas as for example with PPP-elements (polypara phenylen) or integrated metal inlays via the design of microwave coupling as coaxial antenna system, a slotted waveguide antenna or a horn or fan horn structure.

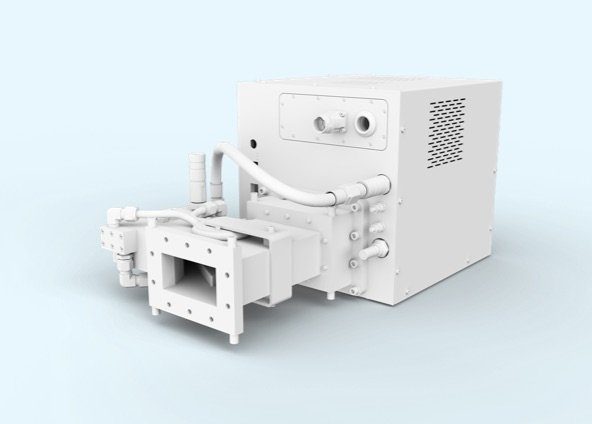

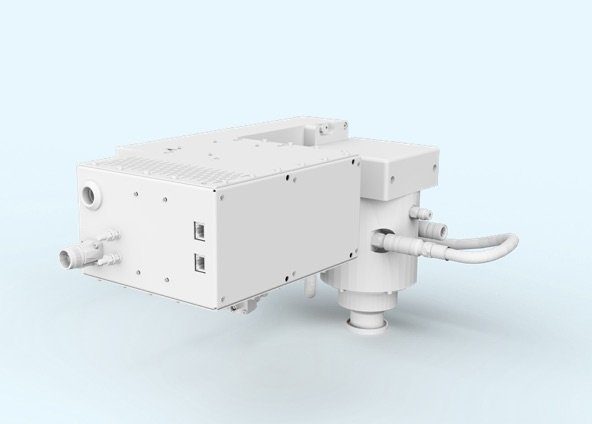

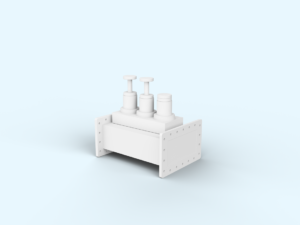

Microwave generators for all power ranges

The antenna system’s supply with microwave energy is realized by serveral, independently adjustable power generators with switch mode power supplies with adjustable microwave power from 1000 W up to 15 kW at 2.45 GHz and 5 kW to 100 kW at 915 MHz. The combination of high-performance generators with more than 6 kW output power and lossless power splitting enable the connection of several antennas to an antenna array and hence to an in-phase energy coupling across wide process tunnel areas. This controlled energy supply permits the construction of heating channels with minimal cross-coupling between the generators and thus an extraordinary utilization of the microwave energy supplied.

A vulcanization solution, tailored to your requirements

No matter whether you require a new highly flexible vulcanization channel with homogenous energy distribution or a low-loss reflector system for efficiency improvement of your existing applicator setup, the microwave technology may offer you an optimal solution. Consult your MUEGGE engineering team for the latest possibilities as well as tailor-made or standard solutions that support your vulcanization project.