How plasma technology solves the challenge of performance degradation in fuel cells

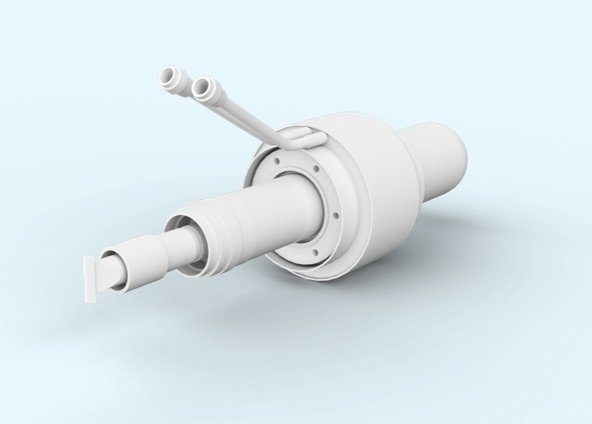

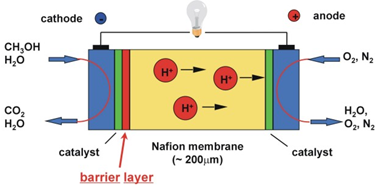

Fuel cells based on ionomer membranes are very important in applications such as zero emissions vehicles. The major disadvantage of commercially available membranes, e.g., Nafion, in direct methanol fuel cells (DMFC) is their relatively large permeability for methanol, which leads to a drastic degradation of the efficiency of the fuel cell. Figure 8 shows the schematic of a DMFC. Plasma surface treatment of such membranes can reduce their permeability to methanol. In addition, the bond strength of the membrane to the catalyst can be significantly improved by plasma surface treatment.

Figure 1: Schematic of a direct methanol fuel cell (DMFC) [8-9]. |

1. Plasma technology to improve water management issues

The porous gas diffusion layer (GDL) is another important component of a fuel cell. It provides a homogeneous gas flow to the catalyst and controls the water content of the cell. In particular, the water management over a wide range of the voltage/current polarization curves is very important for the efficiency of the fuel cell. However, GDLs mostly consist of a strongly hydrophobic material which is critical for a proper water management. A partially hydrophilic GDL is a better choice because it can retain a certain amount of water in the fuel cell.

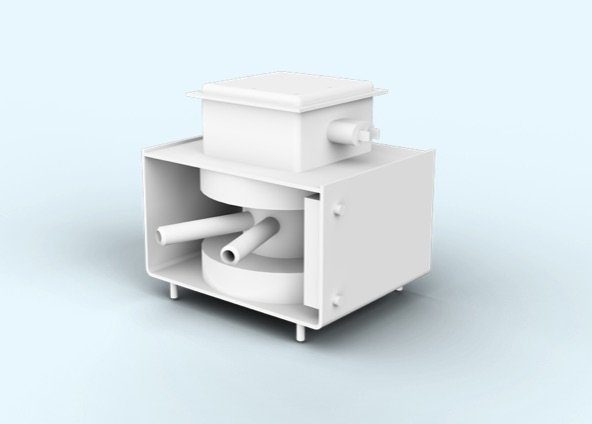

Figure 2: Completely hydrophobic surface of a gas diffusion layer (GDL) showing hydrophilic properties of the areas exposed to the microwave plasma (cf. water droplets adhered to these hydrophilic areas after low-pressure microwave plasma treatment) [9-10].

Partially hydrophilic properties of the GDL can be achieved by e.g., surface treatment of the GDL in a nitrogen plasma process. When the GDL is covered by a perforated plate, only the uncovered areas of the surface of the GDL will be modified in the plasma process. Consequently, the uncovered areas of the surface of the GDL show hydrophilic properties after plasma treatment (water droplets adhering to these areas – Figure 2), whereas the covered areas of the surface of the GDL retain their initial hydrophilic properties.

2. Proven results: Fuel cells show higher performance

The fuel cells with plasma treated GDL show significantly higher cell voltages than the reference fuel cells without plasma treated GDL. This is due to the fact that the membrane of a fuel cell without plasma treated GDL runs dry, especially at higher current densities. When using a plasma treated GDL, a certain amount of water can be retained in the cell leading to a better fuel cell performance.

Plasma technology can boost your performance in many ways. Contact us to find out how we can customize or standardize our systems for your challenges – let us help to fuel your innovations, too.

References

[1] M. Walker, K.-M. Baumgärtner, M. Kaiser, J. Kerres, A. Ullrich, E. Räuchle, J. Appl. Polym. Sci., 1999, 74, 67-73.

[2] M. Walker: Fuel Cells. [online] Homepage: University of Stuttgart, Institute of Interfacial Process Engineering and Plasma Technology (IGVP)

URL: https://www.igvp.uni-stuttgart.de/en/research/plasma-technology/processes/fuel-cells/ [status: June 16, 2021].