Muegge Products

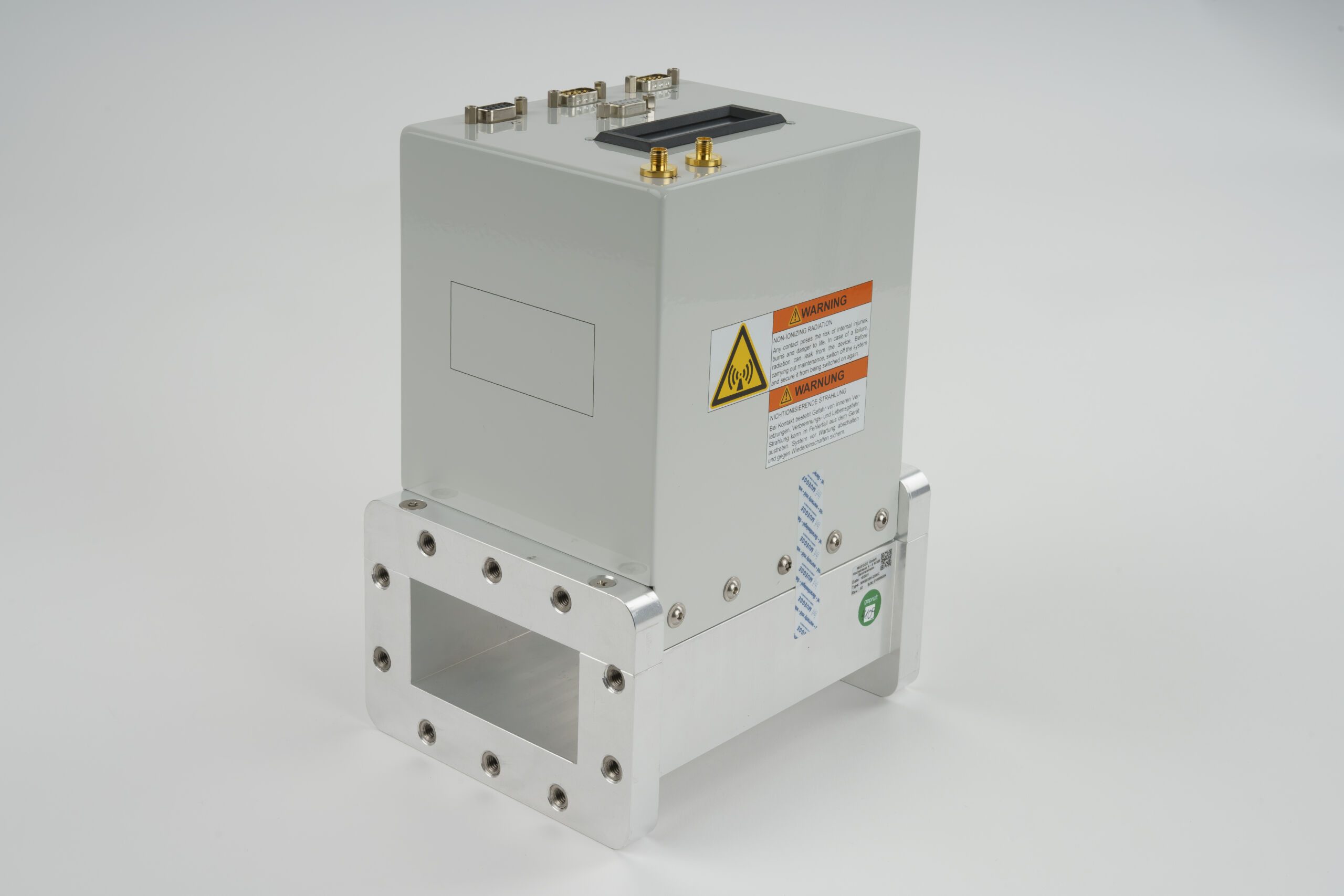

Waveguide components

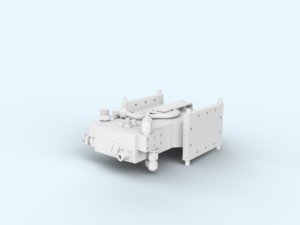

MAGNETRONS FOR INDUSTRIAL HEATING

Regardless of the system design, the magnetron plays an essential role in the generation of electromagnetic energy for industrial heating.

Magnetron types for microwave heating are available as 915 MHz version as well as with 2450 MHz. The 915 MHz version, also known as L-band, we offer with output powers from 5 kW to 100 kW – at 2450 MHz, also known as S-band, our product range covers 800 W to 15 kW.

.

MUEGGE supplies both standard OEM and conversion magnetrons for the industrial aftermarket. Our extensive range for existing equipment supports you in your product development, including in-house manufacturing and laboratory testing.

Typical modifications made to standard OEM magnetrons are

- cooling conversion: air cooling to water cooling

- Modified & customized cooling blocks & water connections

- length and connection type of the coiled cable

- Mechanical changes on the magnetron body

- Modified output powers