How innovative plasma systems bring silicon anodes into lithium-ion battery applications

In 2007 researchers at Stanford University discovered a solution to the challenges associated with the use of silicon in batteries. They were able to store lithium in tiny silicon nanowires by using new nanotechnology techniques and methods. The dimensions of these silicon nanowires are about one thousand times thinner than the thickness of a sheet of paper. The silicon nanowires swell when they absorb positively charged lithium ions, while their physical properties i.e., size and shape, inhibit the silicon from fracturing and breaking apart.

1. Silicon anodes boosting - Performance of lithium-ion batteries

For the reasons mentioned above, silicon is widely considered to be the future material of choice in anode technology. Battery-builders and automakers want to take advantage of its high theoretical charge capacity. It has been proven that batteries with silicon anodes achieve significantly higher energy per unit volume and per unit weight than today’s commercially available batteries based on carbon-anode designs.

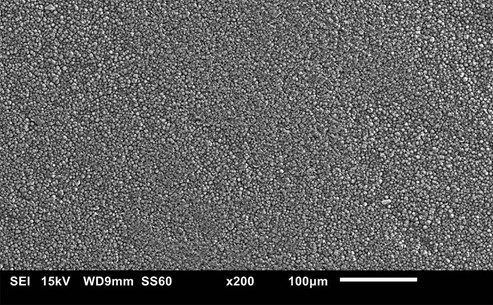

Figure 5: Three-dimensional growth of silicon columns by low-pressure microwave plasma deposition for pure silicon anodes [3].

Manufacturing facilities relying on Duo-Plasmaline technology for plasma enhanced chemical vapor deposition (PECVD) of three-dimensional porous silicon layers have high potential for producing silicon nanowire anodes. Figure 5 shows silicon columns three-dimensionally grown by low-pressure microwave plasma deposition for pure silicon anodes.

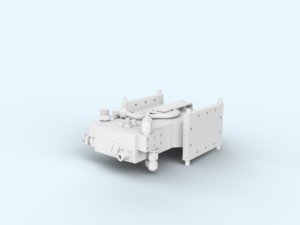

2. Duo-Plasmaline enabling homogeneous and sensitive surface treatment

The combination of Duo-Plasmaline and Plasma Array provides highly efficient surface treatment of even thermally sensitive materials due to high radical densities at low ion energy of the non-equilibrium microwave plasma at low-pressure. The plasma is formed by microwave excitation only, i.e. without the effect of an additional magnetic field. This allows to easily upscale applications for large batches that need a highly precise and homogeneous surface treatment and for materials that require very sensitive processing.

Interested? Would you like to discover how this technology works in detail? Read our in-depth article about Duo-Plasmaline technology. (Link to Article 1)

Should you like know more about how Duo-Plasmaline may benefit your product portfolio and how MUEGGE can customize this technology for you, do not hesitate to contact us.

References:

[3] Applying Solar Technology for Pure Silicon Anodes: Porous Silicon Anodes. [online] Homepage: LeydenJar Energising Technologies, URL: https://leyden-jar.com/technology/ [status: June 16, 2021].