Muegge Products

Plasma systems

-

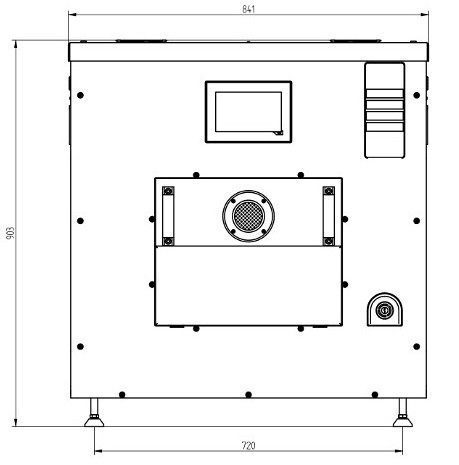

Decapsulation-Tool

Item number: MA1250D-114BB

Type of toolR&D / Pilot Production ToolLine Voltage [V]480Process gas 1O2Process gas 2CF4Process gas 3N2Process gas 4-Process gas 5-Process gas 6-Temperature sensors-Chamber size [mm (inch)]245 x 245 (9.65 x 9.65) -

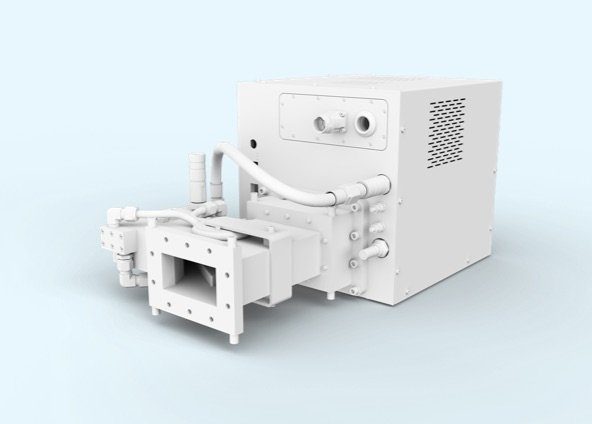

Decapsulation-Tool

Item number: MA3000D-211BB

Type of toolHigh Volume Production ToolLine Voltage [V]400Process gas 1O2Process gas 2O2Process gas 3N2Process gas 4CF4Process gas 5SF6Process gas 6ArTemperature sensors-Chamber size [mm (inch)]320 x 320 (12.60 x 12.60) -

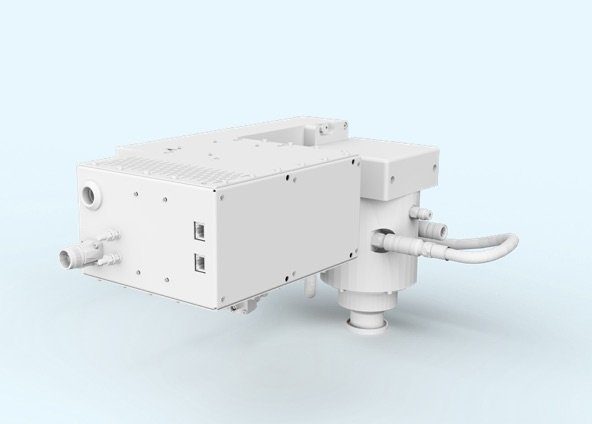

Decapsulation-Tool

Item number: MA3000D-241BB

Type of toolHigh Volume Production ToolLine Voltage [V]400Process gas 1O2Process gas 2O2Process gas 3CF4Process gas 4N2H2Process gas 5SF6Process gas 6N2Temperature sensors-Chamber size [mm (inch)]320 x 320 (12.60 x 12.60) -

Decapsulation-Tool

Item number: MA3000D-281BB

Type of toolHigh Volume Production ToolLine Voltage [V]400Process gas 1O2Process gas 2N2H2Process gas 3CF4Process gas 4N2Process gas 5-Process gas 6-Temperature sensors-Chamber size [mm (inch)]320 x 320 (12.60 x 12.60) -

Decapsulation-Tool

Item number: MA3000D-311BB

Type of toolHigh Volume Production ToolLine Voltage [V]400Process gas 1O2Process gas 2O2Process gas 3N2Process gas 4ArProcess gas 5CF4Process gas 6SF6Temperature sensors-Chamber size [mm (inch)]320 x 320 (12.60 x 12.60) -

Stripping-Tool

Item number: MA0000D-001BB

Type of toolR&D / Pilot Production ToolLine Voltage [V]208Process gas 1O2Process gas 2N2Process gas 3N2Process gas 4-Process gas 5-Process gas 6-Temperature sensors2Chamber size [mm (inch)]245 x 245 (9.65 x 9.65) -

Stripping-Tool

Item number: MA1250D-110BB

Type of toolR&D / Pilot Production ToolLine Voltage [V]208Process gas 1O2Process gas 2N2Process gas 3N2Process gas 4-Process gas 5-Process gas 6-Temperature sensors2Chamber size [mm (inch)]245 x 245 (9.65 x 9.65) -

Stripping-Tool

Item number: MA1250D-112BB

Type of toolR&D / Pilot Production ToolLine Voltage [V]400Process gas 1O2Process gas 2CF4Process gas 3N2Process gas 4-Process gas 5-Process gas 6-Temperature sensors2Chamber size [mm (inch)]245 x 245 (9.65 x 9.65)

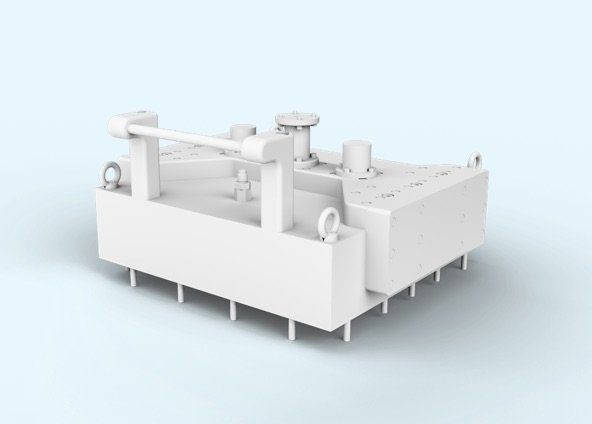

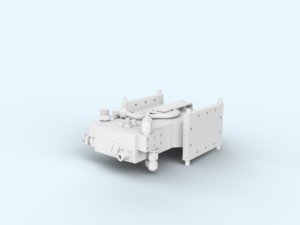

PLASMA SYSTEMS

Semiconductor components have become indispensable for products of our daily life. Nobody wants to imagine a future without them. However, the manufacture of these devices requires highly sophisticated equipment and in-depth process knowledge – and as technology advances, the challenges for plasma and for the control of plasma-assisted applications are increasing.

We work closely with customers and research institutes to understand the market and provide you with optimal microwave solutions – going beyond conventional plasma approaches to develop products that will significantly improve your results and processes. Our leading position as a manufacturer of microwave-assisted plasma products helps you to enter the market faster and more cost-effectively with customized systems:

.

- SU-8 removal

- Highly selective removal of organic materials

- Non-oxidizing chemistry for cleaning of oxygen sensitive materials

- Cleaning of 3D structures

- Damage-free cleaning of sensitive surfaces (e.g. sensors)

- Isotropic chamber cleaning

- LIGA process (lithography, electroplating and shaping)