While developing thermoprocessing equipment, testing of prototypes and numerous repetitions cost plenty of

time and resources. 3D simulation capabilities allow you to speed up your prototyping phase, implement

adjustments promptly whilst offering a detailed and comprehensive view to optimize your microwave

application. Learn what you can get out of virtual prototyping tools as we use them at MUEGGE, to power

your projects.

Choose the ideal simulation method for your project

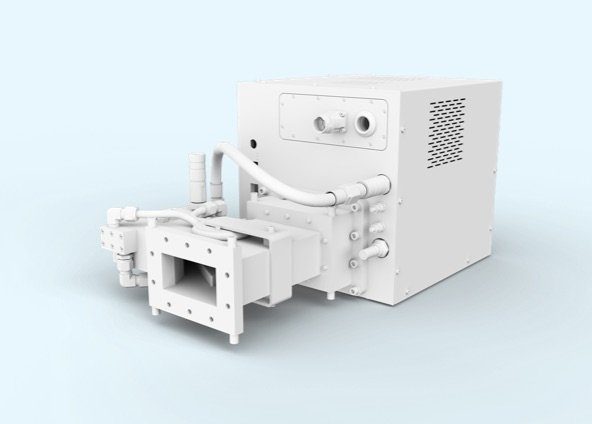

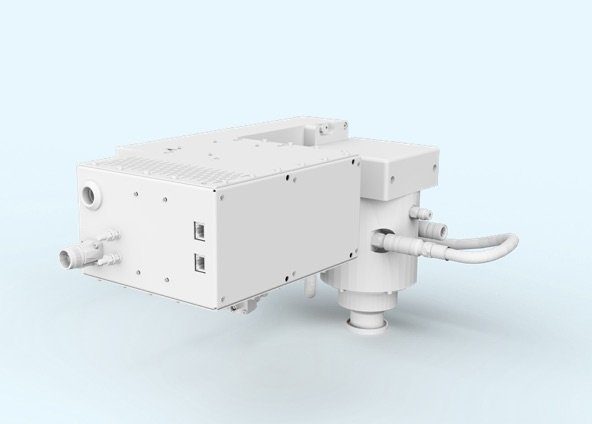

3D simulation tools cast a realistic and accurate view on your power requirements, applicator dimensions and impedance matchings without having to deal with the production of complex samples. But not every tool and method makes sense for anyone – to save time and achieve best results, consult experts to analyse your microwave material properties and suggest the simulation and analysis variant that fits best to your project goal.

Use high performance 3D-analyzing for maximum speed and precision

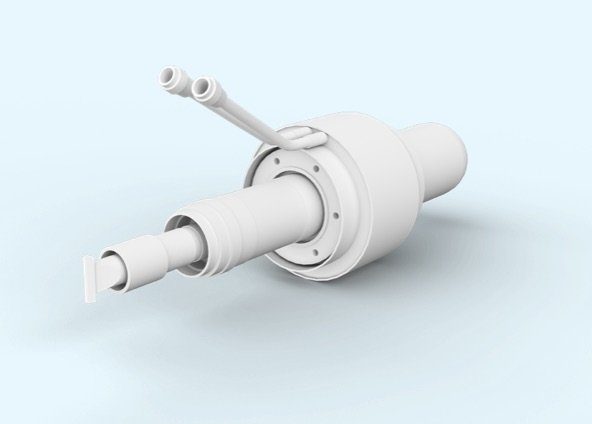

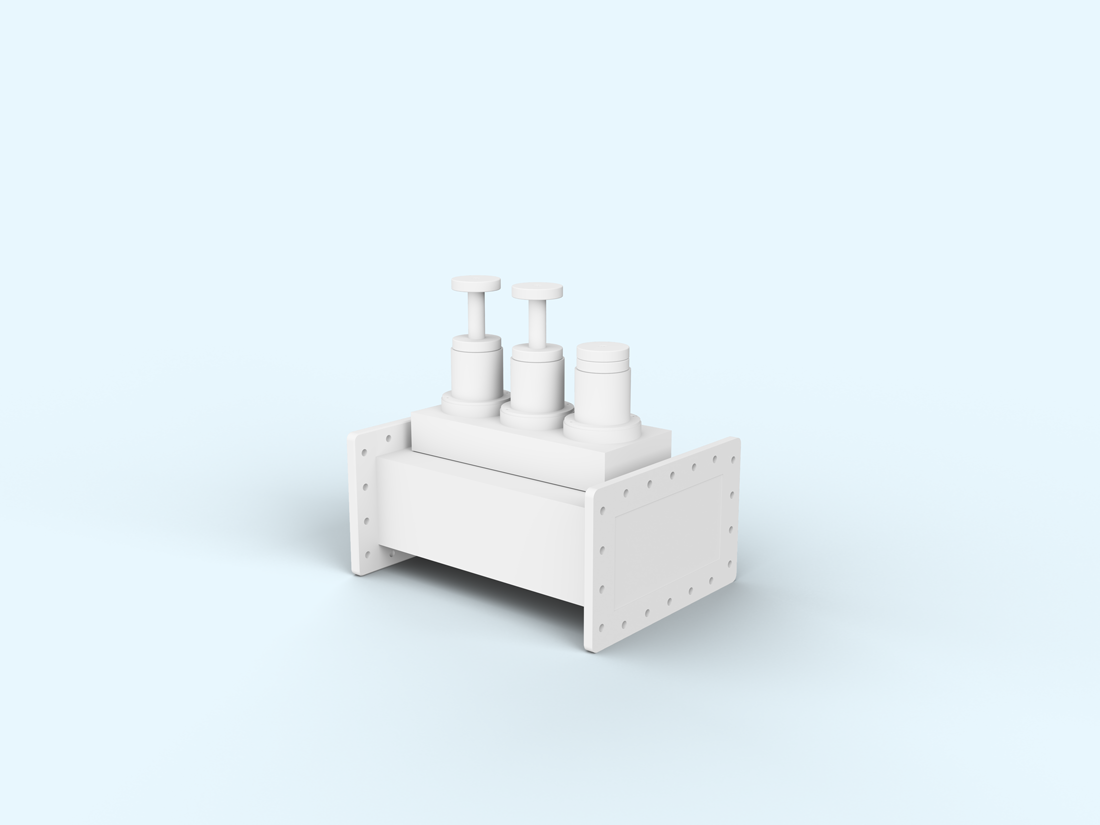

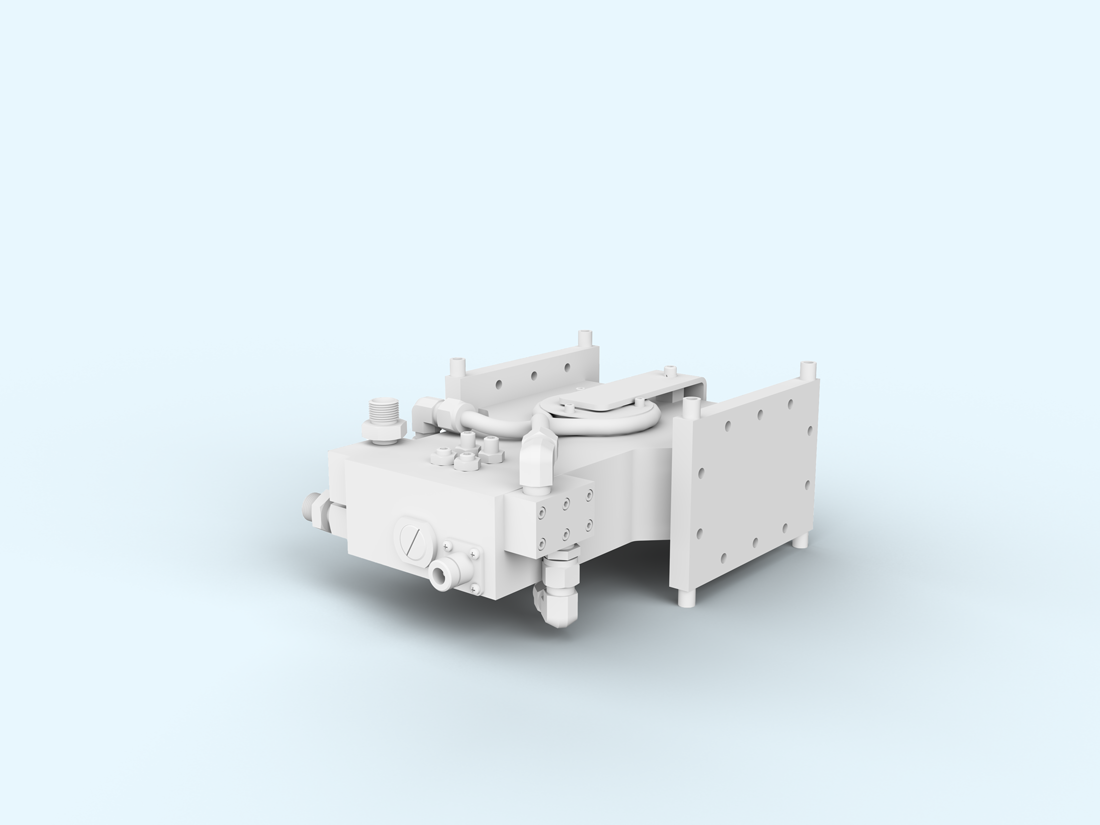

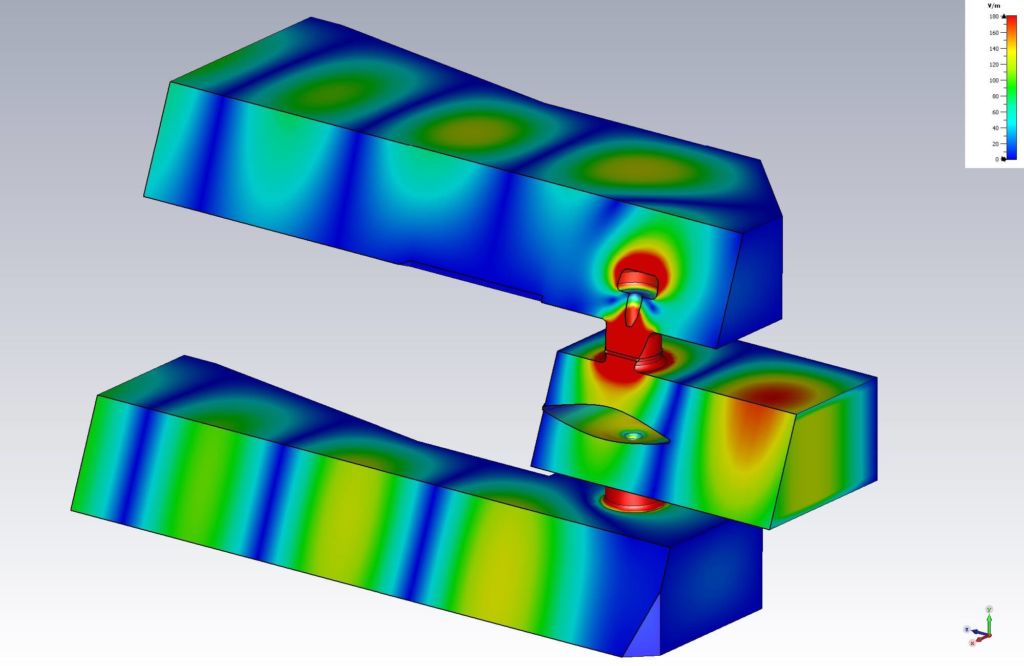

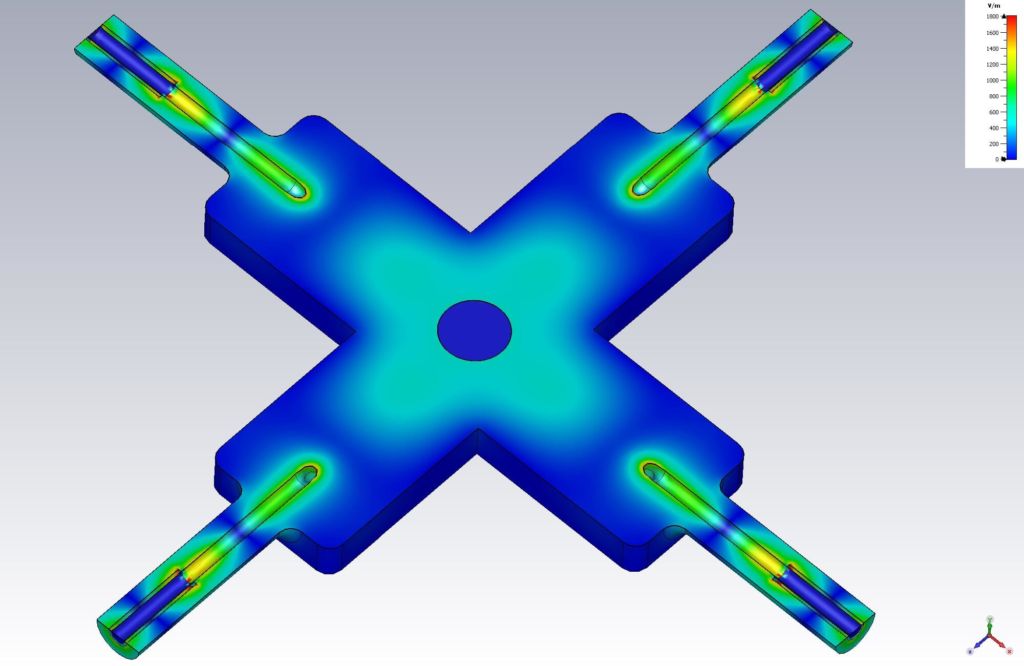

Don’t compromise on the quality of your microwave simulation tools – low-performing server structures or outdated systems corrupt the advantages you get from this technology. By using a high-performance 3D-electromagnetic-analysing software it is possible to carry out jobs such as 3D-designing, EM-analysing or optimizing electromagnetic components within a short time with the utmost precision. Simulation possibilities at MUEGGE, for example, embrace a wide field of applications starting from a simple coupling analysis of waveguide components to a complete simulation of the field strength distribution in complex multimode applications.

Visualization from flexible nanostructures to industrial multi-hybrid-application

- Analysing entire PCB-boards with discrete components in HF-circuits

- Complete photoresist removal at high speed (>200 µm/h) with high selectivity with no altering of underneath layers

- Many more individual features

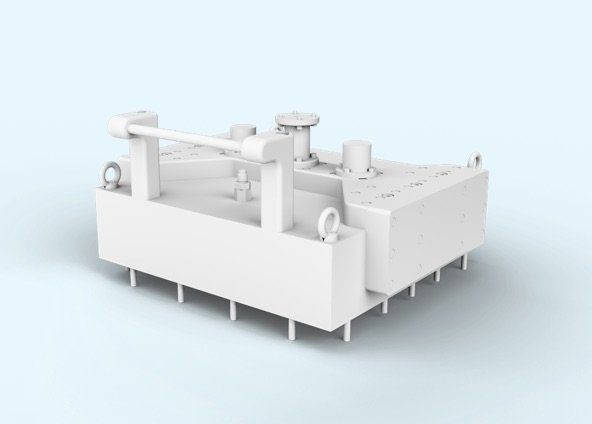

Take advantage of hybrid simulation

Gather comprehensive datasets for scaling processes and expanding the good’s output by coupling individual solver types. These hybrid simulations enable you to analyse and virtualise the complex coaction of high frequency energy and additive electromagnetic influencing systems in an efficient and, at the same time, simple way. This is crucial to determine the efficiency factor of antenna systems or heating performance of resonators.

Employ 3D-filter structures as basis for EMV and labor security

Thanks to 3D-HF-structure simulations it is possible to reproducibly design frequency microwave filter systems for a low-emission operation of half-open, continuously operating microwave applicators. By a continuous spatial optimization of the choke inlet and outlet structures we are able to consistently guarantee the observation of EMV-threshold values for all applications that are heated by microwaves or by hybrid technologies.

3D simulation in short: Reducing time, improving quality

The consequent utilization of the 3D-simulation as a direct process step in your microwave component

development allows compliance with shortest possible development cycles – no need for long test series with complex sample types and numerous repetitions. It offers considerable advantages for a prompt product adjustment at very low development costs. Ask our experts how we can bring simulation power to your project – just mail, call or ping us on LinkedIn.