MUEGGE’s microwave plasma torches are microwave excited plasma sources designed to work at atmospheric pressure and to generate a contact-free plasma while ensuring stable operation for a wide parameter range of gas-types, gas flow and microwave power at 2.45 GHz and 915 MHz. MUEGGE’s microwave plasma torches are well suited for both the synthesis of special gases and for assisting chemical reactions with highly reactive gas species. This is the key for many Power-to-X applications such as Power-to-Gas and Power-to-Chemicals.

What you can expect

Atmospheric Plasma?

Wide range of services for all application areas

Power-to-X applications in industry and research

The electric gas burner – > 1400°C without chemical fuels

Conclusions

1. Atmospheric Plasma?

In physics, a technical plasma is described as the 4th aggregate state of matter and it consists of ions and electrons as well as other excited gas species and highly reactive charge carriers. Since in almost complete local thermal equilibrium with a high degree of ionization, the atmospheric microwave plasma is a special form of a technical plasma. In contrast to other plasma systems, microwave plasma is generated in non-contact cavity resonators and does not cause burn-off of energy-carrying electrodes or media contamination due to contact between plasma and hot gas-carrying components. The plasma torches have been measured to achieve gas temperatures of up to 3500 K, temperature determined by optical emission spectroscopy.

2. Wide range of services for all application areas

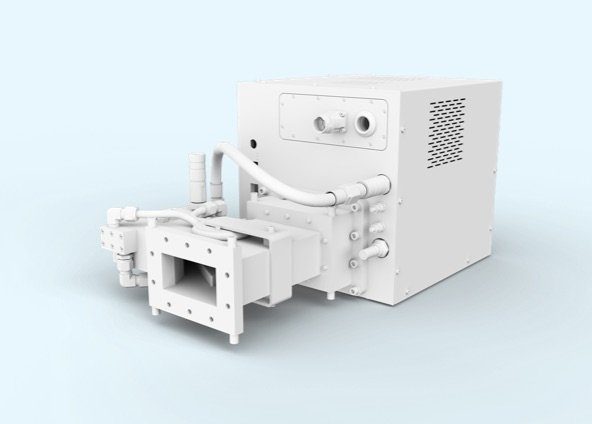

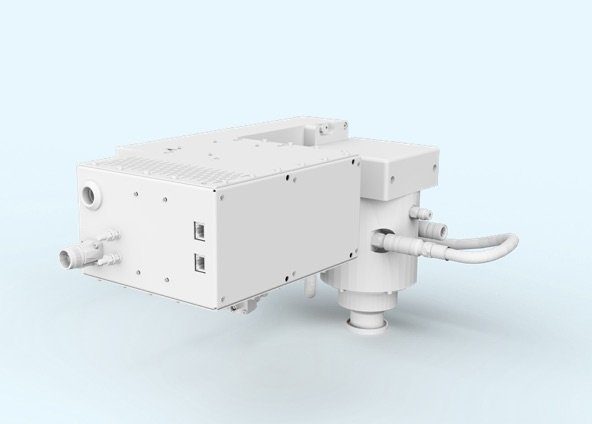

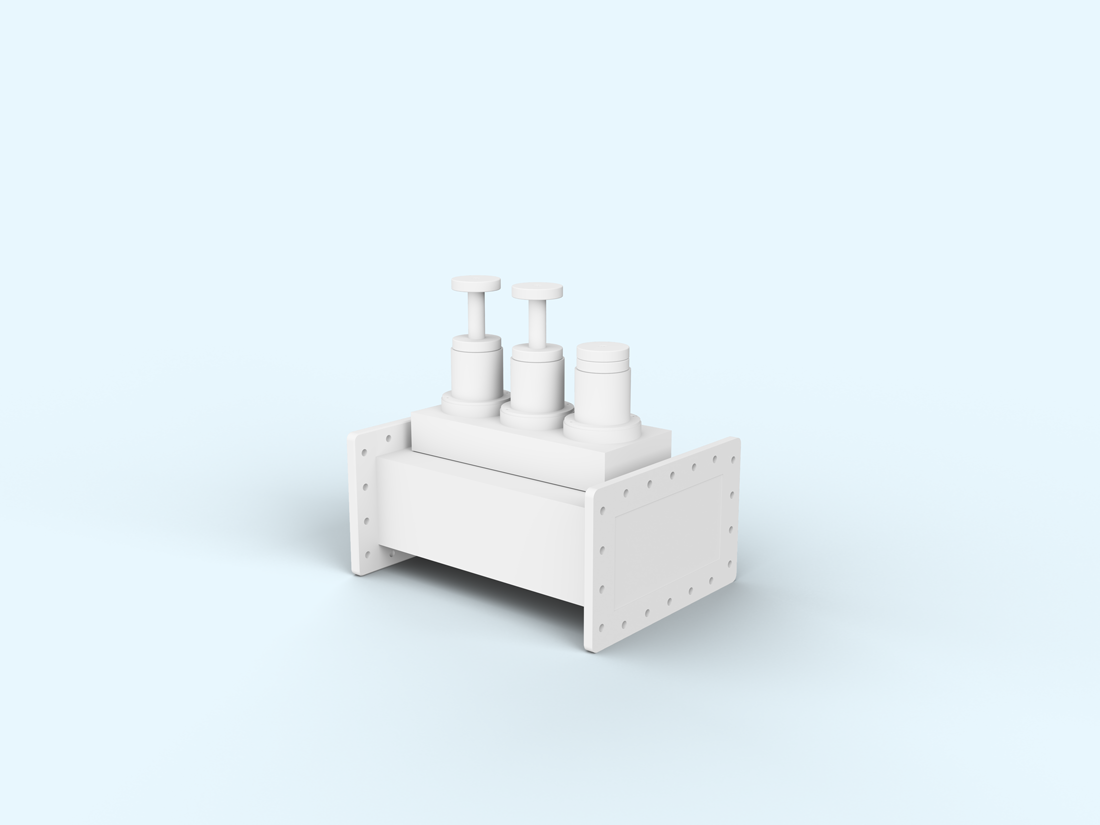

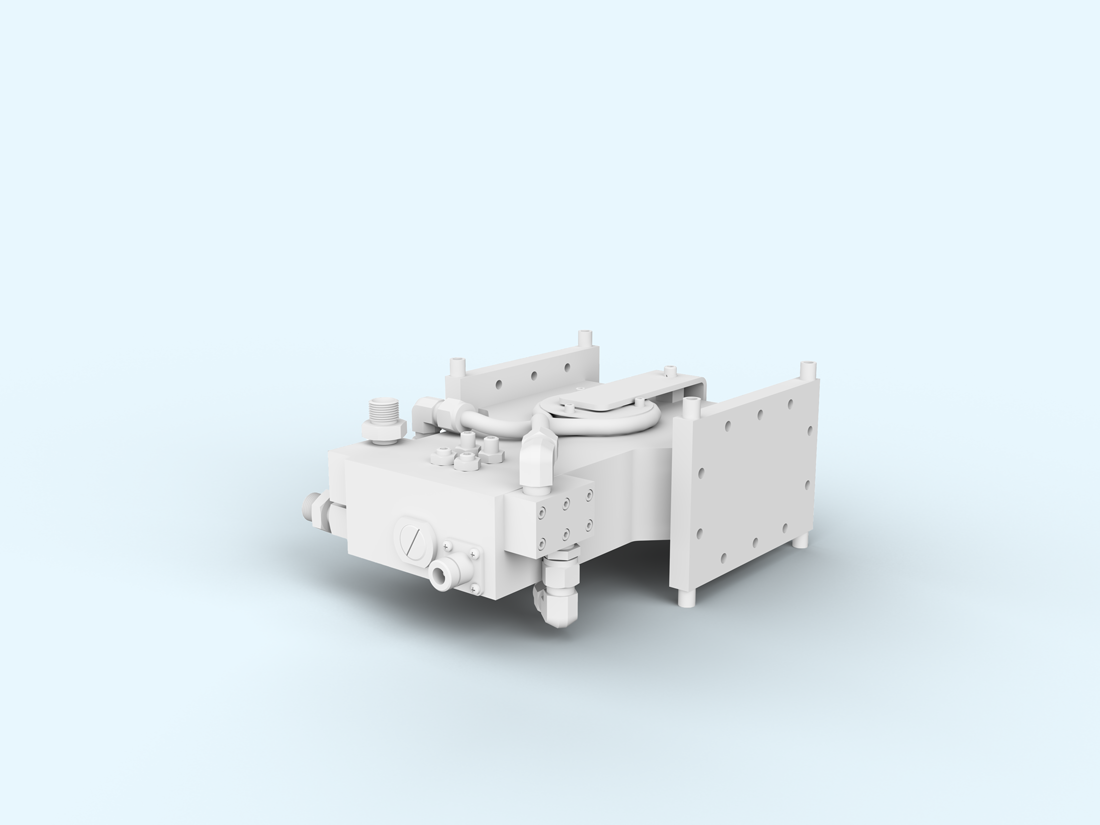

The new generation of MUEGGE’s microwave powerheads enables the built of compact plasma sources at atmospheric pressure used for both surface and volume treatment. The Atmospheric Plasma Source (APS) can operate at microwave frequencies of 2.45 GHz and 915 MHz. Figure 1 shows two Muegge microwave plasma torches running at 2.45 GHz, 6 kW (left) and 3 kW (right). Microwaves are fed into the plasma source as to create a very high electromagnetic field concentration in the middle of the microwave cavity. In this region, the plasma is ignited and sustained. Several kilowatts of microwave power can be absorbed by the plasma, as such leading to gas temperatures up to 3500 K.

Figure 1: 2.45 GHz microwave plasma torches running at 6 kW (left) and 3 kW (right)

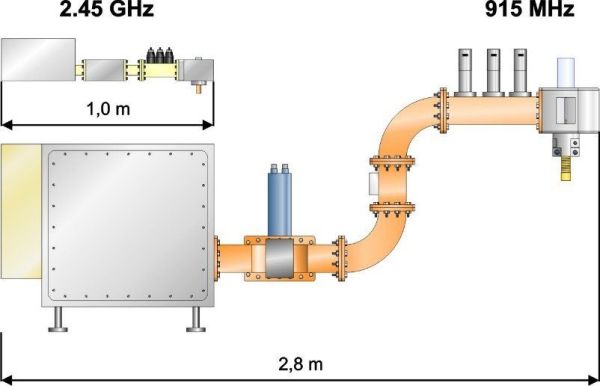

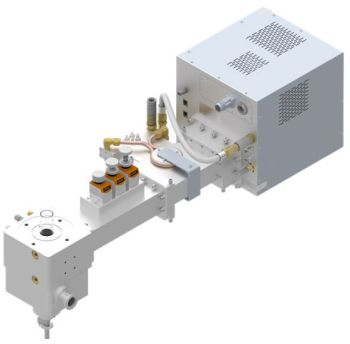

The APS systems are available up to 6 kW at 2.45 GHz and up to 75 kW at 915 MHz. Processes are easy to scale from a 2.45 GHz lab-system for development to an industrial 915 MHz high-volume system. Footprints of two different systems are shown in figure 2.

Figure 2: 2.45 Scalability from a 2.45 GHz to 915 MHz

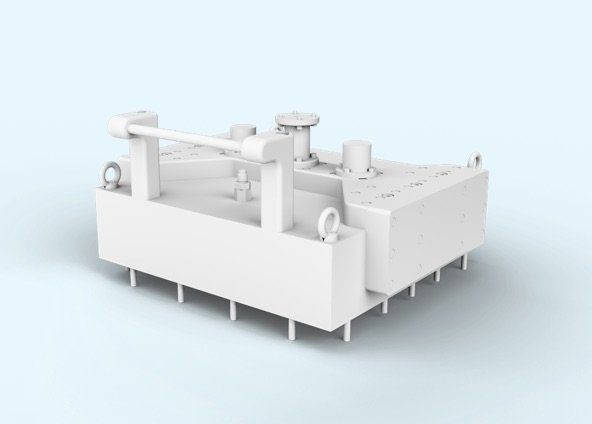

While APS systems operate without an isolation between the process area and the surrounding, the downstream source separates the process gases from the environment. Such a system is designed to cover the pressure regime between 10-500 mbar and operates up to 75 kW (figure 3). These unique properties make it a primary choice for the treatment of huge gas flows.

Figure 3: 915 MHz microwave plasma downstream source running at 60 kW

3. Power-to-X applications in industry and research

During periods of high output, electrical energy production from renewable energy sources,e.g., sun, wind, water, can easily exceed demand and as such, the surplus usually gets wasted. To maintain a stable public mains electricity supply, surplus energy from renewable sources has to be stored, which at present is a big challenge, probably the biggest challenge of the energy transition. Power-to-X is a general term summarizing all technologies for the conversion of surplus energy from renewable sources into storable matter. Power-to-X has two big advantages over other technologies:

- Storable matter can be converted back to energy anytime and is easily transportable using existing infrastructure;

- It serves as basic material to produce for example, more complex molecules for the chemical industry or CO2-neutral synthetic fuels to replace fossil fuels.

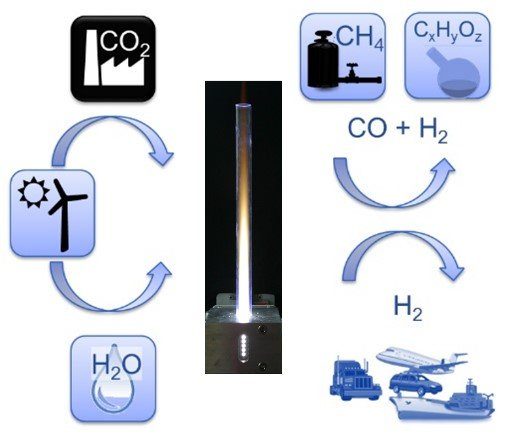

Figure 4 shows some examples of Power-to-X applications based on microwave plasma technology.

Figure 4: Some examples of Power-to-X applications based on microwave plasma technology (left) and standard 6 kW, 2.45 GHz APS (right)

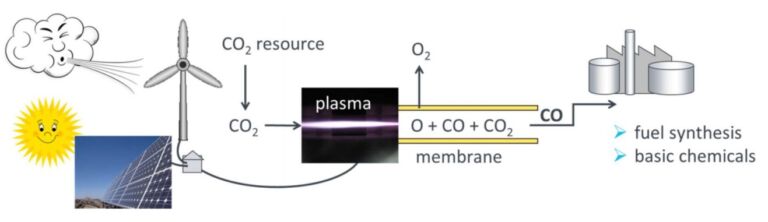

Storage of surplus electrical energy from renewable sources is a crucial factor for maintaining the stability of the public mains electricity supply. Carbon dioxide (CO2) conversion is a promising approach for storing surplus renewable energy. The concept of CO2 conversion is based on the dissociation of CO2 into oxygen radicals (O) and carbon monoxide radicals (CO) in an atmospheric pressure microwave plasma process, see Figure 5.

Carbon monoxide (CO) is an industrial gas, which is widely used in industrial chemical manufacturing. CO can be converted into base chemicals and chemical energy carriers such as methanol or methane using existing infrastructures via conventional chemical processes.

Figure 5: Schematic of CO2 conversion for Power-to-Chemicals applications.

CO2 conversion can be efficiently performed with a high-power microwave plasma torch using excess electrical energy from renewable sources. After the separation of the oxygen from the gas mixture, the remaining CO can be converted into syngas or into higher hydrocarbons. Hence, a zero-emission carbon cycle can be established.

This is shown in Figure 6 using a perovskite membrane.

In university research, the microwave plasma torches are not only used for carbon dioxide (CO2) conversion but also for the analysis and the optimization of high temperature combustion processes (projects funded by EU).

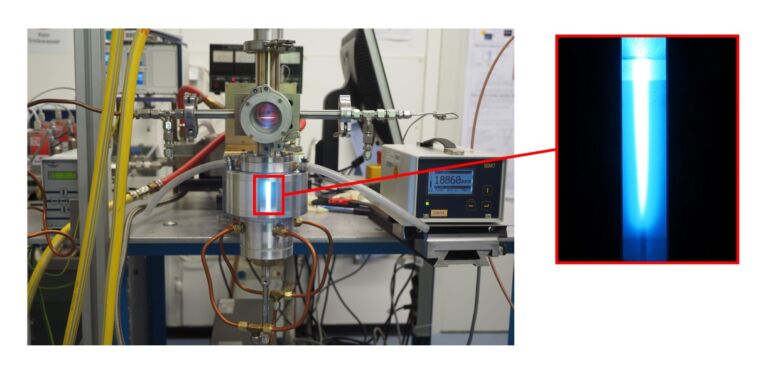

As shown in Figure 7, the microwave plasma torch can achieve an unrivalled flexibility for the supply of inert hot gases due to a very fast starting behaviour and a thermal application range exceeding by far any conventional heat exchanger.

Figure 7: Hot combustion tests with 915 MHz plasma torch for engine and fuel research at TU Darmstadt

4. The electric gas burner - > 1400°C without chemical fuels

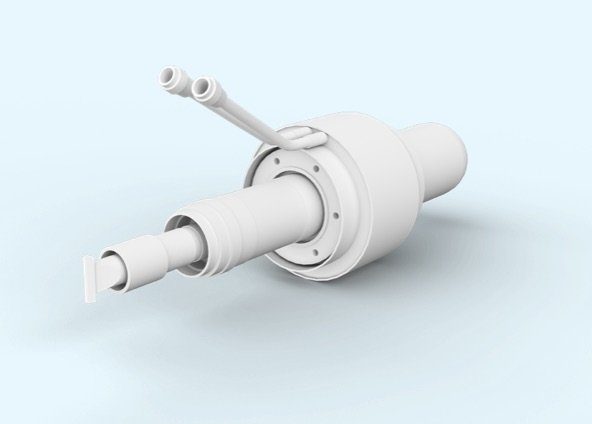

Another interesting application of the microwave plasma torch is the supply of hot gases. Dedicated plasma systems are available for different pressure ranges and for a large variety of applications, including surface-activation, oxidation-free processing of raw materials under inert gases, and CVD processes for growing synthetic crystals, i.e. carbon deposition.

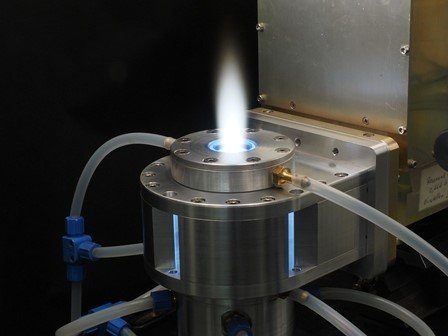

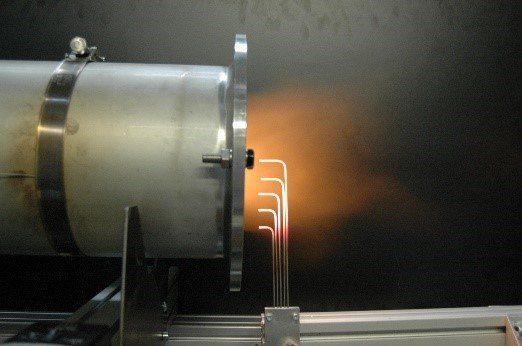

The 915 MHz microwave plasma torch shown in Figure 8 operating between 20 kW and 75 kW can achieve a gas outlet temperature above 1400 °C at gas flows above 120 m³/h.

Figure 8: Flame of the 915 MHz plasma torch at 60 kW microwave power

The high efficiency and versatility of the 915 MHz plasma torches allows the direct replacement of traditional gas or liquid fuel burners in existing furnace systems, especially for low load modulation furnaces. Moving from conventional energy sources to electrically driven microwave or plasma heating, customers can dramatically lower their cost of ownership (CoO) and cut down the expenses related to process CO2 footprint according to the requirements of our future industrial environment.

5. Conclusions

Due to its wide and versatile utilization range, MUEGGE’s latest generation of atmospheric pressure microwave plasma torches enables a wide range of industrial and research processes. The burner technology offers highly efficient and economic applications for:

- Production of synthesis gas;

- Cracking of hydrocarbons in reforming processes;

- Heating of inert gases;

- Usage as CO2-neutral gas burner.

The contactless plasma generation within a resonator structure is the key property of these microwave energy driven high temperature applications. At the same time, microwave plasma systems offer the best alternative to build decentralized supply networks with CO2-neutral hydrogen-based fuel gases for energy storage or for direct and location-independent use.

Power-to-X technologies based on microwave heating and microwave plasma processes are innovative solutions to convert electrical energy from renewable sources into material resources such as hydrogen, carbon monoxide, and synthetic gases for storage and recycling, e.g., conversion of electrical energy into gaseous or liquid fuels or chemicals for long-haul trucking, shipping and aviation.