Complete removal of thick photoresist needs proper endpoint detection

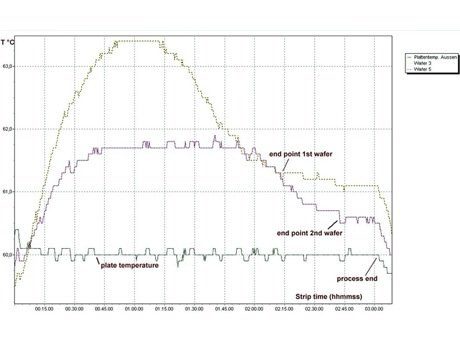

Applying microwave (MW) plasma to remove thick resist such as used for micro-machinery and microelectromechanical systems (MEMS) requires adequate endpoint detection to limit the unnecessary exposure of sensitive structures and surfaces to reactive gases. The unique properties of microwave assisted plasma allow easy and accurate endpoint detection using temperature sensors.

Microwave Plasma – Isotropic resist removal with least thermal load

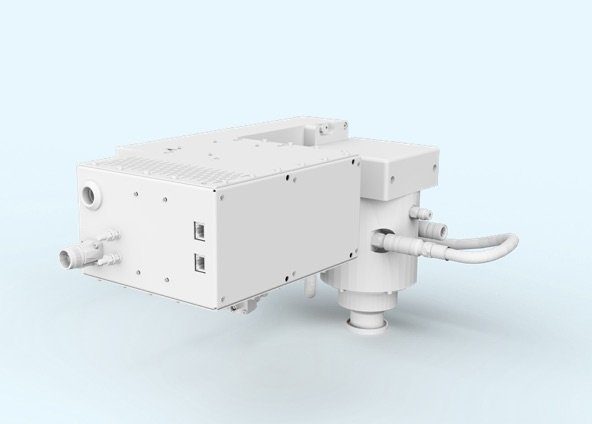

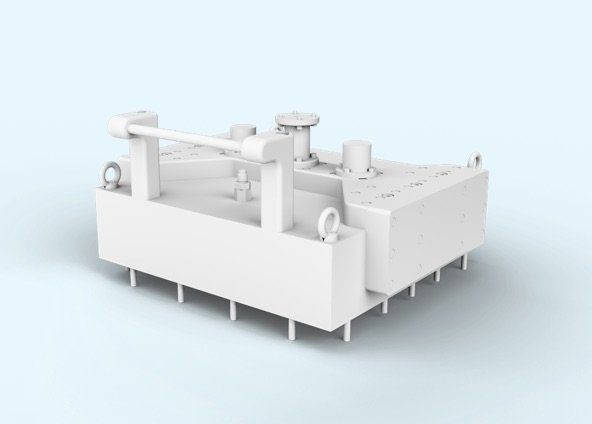

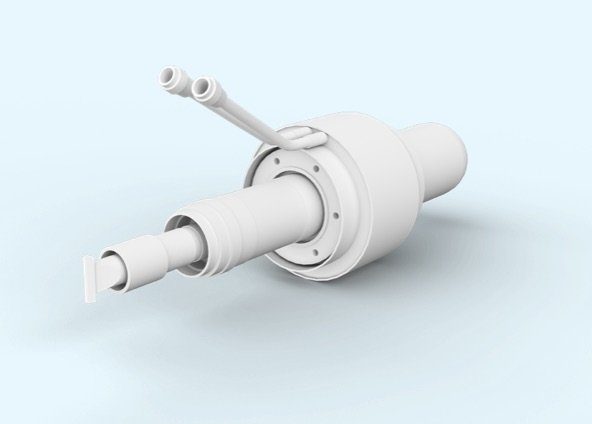

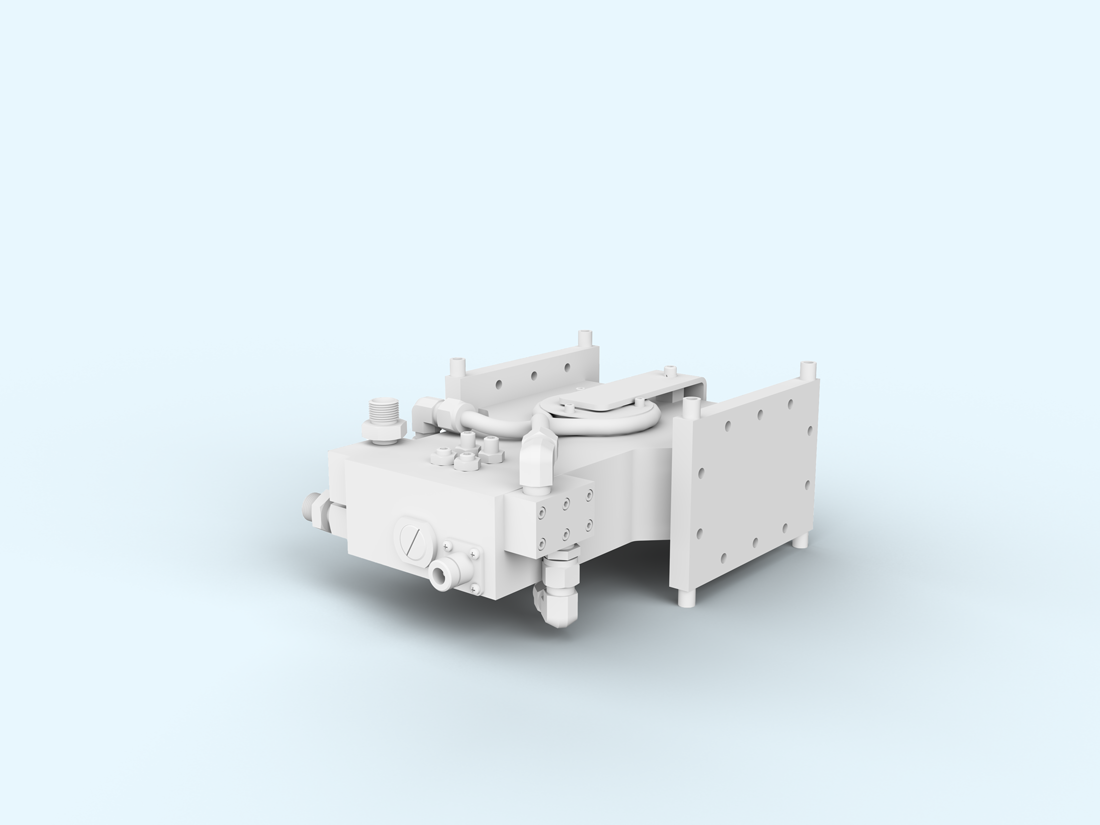

RF-plasma exposes the substrate to a relative high amount of charged species (ions) related to the energy distribution in the plasma. These ions transfer kinetic energy when hitting the surface of the substrate causing it to heat up. Depending on the process conditions, this heating-up is critical for the integrity of the substrate, hence cooling is required to stay within the specified temperature range. In the case of Muegge’s microwave assisted remote plasma source, the energy transfer is extremely low, no charged particles are released into the process chamber. As a result the substrate remains cold, the only heat-source it is the chemical reaction of the exothermic resist removal. The related temperature change can be used to track the progress of the cleaning process.

MUEGGE’s solution – accurate, reliable and repeatable

Although optical endpoint detection is mature and reliable, it requires substantial invest into additional equipment like interferometry and sophisticated control algorithms. For less demanding applications (e.g. photoresist removal) customers are looking into less complex solutions. Temperature as indicator for the reaction progress is an obvious choice but usually not easy to track because of physical side-effects of the plasma generated species (e.g. temperature raise due to sputtering).

Radical based photoresist removal allows precise tracking of

the heat released by the chemical reaction only. Data collection is easy to realize, reliable and repeatable.

Endpoint detection for different substrate samples

Advantages of temperature-based endpoint detection

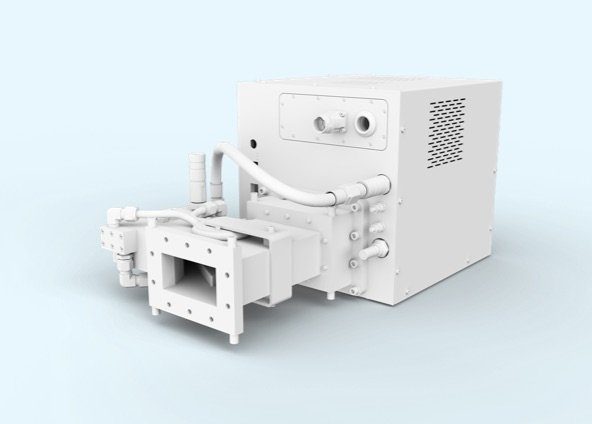

Different applications require different technologies for endpoint control in high volume production. Using the measurement of substrate`s temperature during photoresist-removal offers a reliable method to detect endpoint, however, RF-plasma technology produces too much noise to separate the reaction-heat from other heating-up mechanisms. Microwave-assisted photoresist removal allows to collect temperature data with sufficient resolution for endpoint detection. Temperature sensors work reliably for the typical pressure range of microwave-assisted plasma, no additional hardware is required. The signal is stable and free of interference as it only depends on the chemical reaction taking place on the substrate. Over-etch can be easily derived from the endpoint, changes in the process chamber (e.g. leaks, gas-flow) will reflect in the endpoint curve and help to adjust preventive maintenance cycles. The detection is inherently very stable and does not need re-calibration in case of process adjustments. It is a feature of the Muegge microwave systems (STP series) and proven in high volume production.