Removal of thick and embedded photoresist – A case for isotropic microwave plasma

Microwave plasma is the perfect solution for removing thick resist such as used for 2- and 3-dimensional structures in micro-machinery and microelectromechanical systems (MEMS). The advantage of microwave (MW) plasma over RF-plasma is crucial - organic materials can be cleared without damage or altering of subjacent layers and structures. Microwave Plasma – Isotropic and fast resist removal

Whereas RF-plasma is the most common method to etch thin layers, it is not ideal to remove thick photoresist from 2- and 3-dimensional structures because of its anisotropic (directional) nature. The reactive species generated in the RF-plasma are directed towards the substrate and not able to remove the resist within 3D-structures, i.e. if protected from direct exposure. Additionally, heat transfer due to sputtering will cause thick photoresist (PR) to polymerize during anisotropic etching when getting hot.

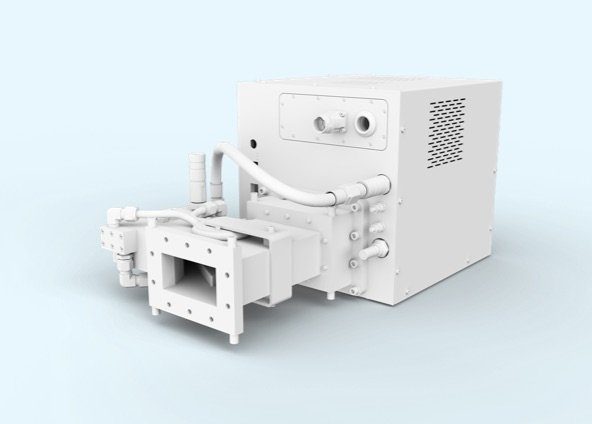

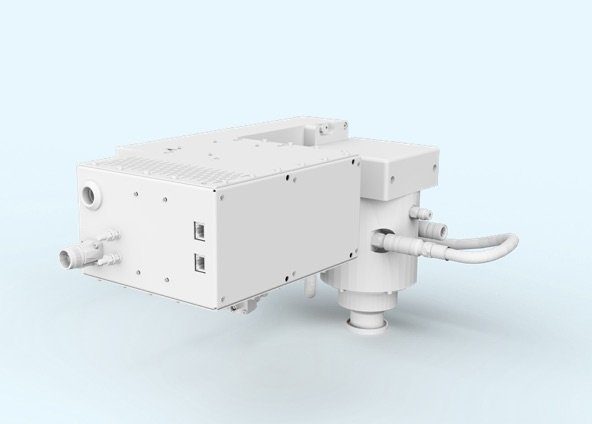

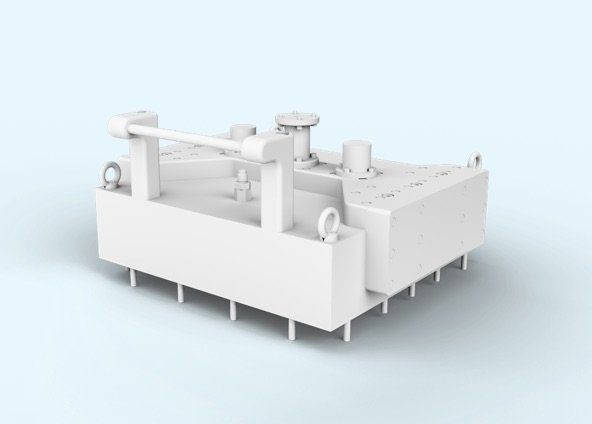

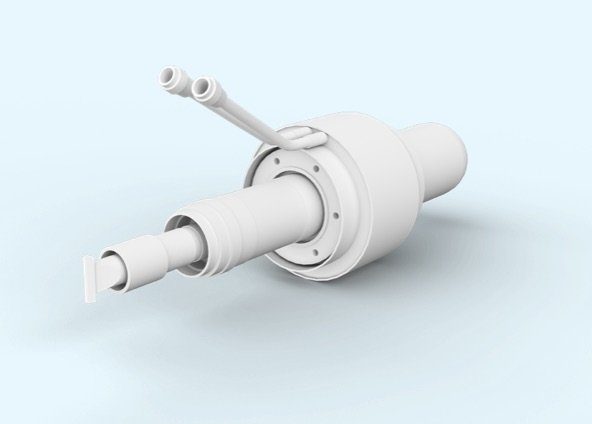

MUEGGE remote microwave-plasma addresses these issues

- No plasma generated outside the remote source, only radicals are reaching the substrate. Therefore the MW-assisted remote plasma system is ideal for applications which absolutely need to avoid physical effects, such as ion bombardment and high thermal load – no polymerization or carbonization occurs and the resist is removed even from most sensitive surfaces (e.g. sensors).

- The radicals generated are initiating a chemical reaction only at the surface of the substrate. As a consequence, the thermal load is extremely low which guarantees damage free isotropic etching at high rates.

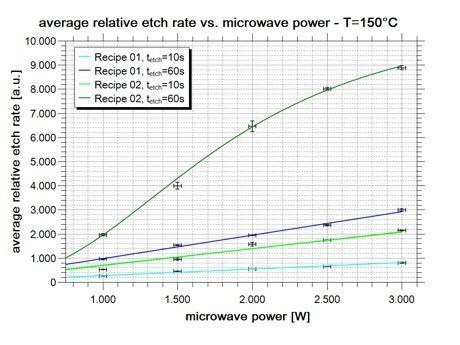

Figure 2: Average relative etch rates of standard photoresist for different microwave powers at 150 °C vs.applied microwave power. Exemples for two plasma recipes and different etching times.

Advantages of MW assisted plasma process

Manufacturing of MEMS requires a wide range of PR-removal applications. Microwave-plasma allows to adjust for very high striprate at high selectivity but also the etching on top of CF4- and O2-sensitive materials. MW assisted plasma is specially designed for fast etching without attacking sensitive parts of the substrate. It provides the capability for complete resist removal at high speed (>200um/h) and high selectivity with no altering of underneath layers. The radicals generated only produce chemical reactions at the surface, leading to pure chemical etching at high rates with extremely low thermal load, thus keeping the effect on the substrate as low as possible. No measurable electrical fields and ions are present at substrate level, hence no plasma induced charging damage of critical structures occurs.

MW assisted plasma is highly environmentally compliant due to nearly complete dissociation of process gases like CF4.